Đơn vị cuộn quạt (Fcu), Là thành phần cốt lõi của điều hòa không khí cuối trong hệ thống HVAC, Cung cấp quy định nhiệt độ chính xác và nhiệt độ môi trường thoải mái cho các tòa nhà, Phòng và những nơi khác thông qua lưu thông không khí trong nhà hiệu quả và trao đổi nhiệt. Trong bài viết này, Chúng tôi sẽ phân tích các nguyên tắc kỹ thuật của nó, application scenarios and cutting-edge trends to help you fully grasp this key equipment!

Working Principle of Fan Coil

How it works

Recirculation of air: The indoor air enters into the FCU through the air outlet, and the motor rotation drives the impeller to send this air which needs to lower or raise the temperature to the heat exchanger (hot/cold water or refrigerant), this treated air is sent to the indoor through the air outlet.

Temperature adjustment: Installation of a room thermostat with adjustable air speed and control of the heating and cooling modes on the wall or in the location where the desired temperature is to be achieved. Adjust the operation mode of the FCU according to the desired temperature setting.

Heat exchange type

Water System: It can be classified into two types based on different configurations of the supply and return pipe systems: the 2-pipe system and the 4-pipe system.

2-Pipe System: Consists of 1 supply pipe and 1 return pipe. Cold water is supplied for cooling purposes, and hot water is supplied for heating purposes, with the supply pipeline switched via valves.

4-Pipe System: Comprises 2 supply pipes (cold water supply and hot water supply) Và 2 return pipes (cold water return and hot water return). The cold and hot water pipelines operate independently, enabling simultaneous supply of both cold and hot water. The supply of cold and hot water is controlled by electric valves.

AC fan coil unit vs EC fan coil unit

Fan Motors: AC motors (alternating current motors) or EC motors (electronically commutated DC motors)

AC Motors

- Working Principle: AC motors are driven by a rotating magnetic field generated by alternating current. Stator windings are supplied with AC power, and the rotor rotates under the force of the magnetic field.

- Hiệu quả năng lượng: AC motors have a slip rate during operation, leading to significant energy loss. Their efficiency typically ranges from 60% ĐẾN 75%.

- Speed Regulation Performance: AC motors require complex speed control methods, with a limited speed adjustment range, low precision, and complicated control mechanisms.

- Control Method: AC motor control is relatively simple, generally using contactors, relays, vân vân., to control start/stop and speed regulation

EC Motors

- Working Principle: EC motors are brushless DC motors that replace mechanical commutators with electronic commutators. They switch the current direction in the windings based on signals from position sensors to drive motor rotation.

- Hiệu quả năng lượng: Through precise electronic control, EC motors can operate efficiently under different working conditions, achieving an efficiency of 80% ĐẾN 90% with significant energy-saving effects.

- Speed Regulation Performance: EC motors can easily achieve wide-range and high-precision speed regulation by adjusting the input voltage, meeting the needs of various working conditions.

- Control Method: EC motors can be connected to intelligent control systems to enable functions such as remote monitoring and automatic adjustment, facilitating building automation management.

Heat Exchanger:

Uses copper tubes with high heat transfer coefficient as the base tubes, and is equipped with aluminum fins with high thermal conductivity to increase the heat dissipation area.

Structural Composition

Mainly composed of copper tubes and corrugated aluminum fins, which are combined through a hydraulic tube expanding process.

Working Principle

When hot or chilled water flows through the copper tubes, it exchanges heat with the air outside the tubes. The fan drives air to flow between the aluminum fins, enabling heat transfer between the air and the chilled/hot water in the copper tubes, thus achieving cooling or heating of the air.

Advantages

- High Heat Transfer Efficiency: Copper tubes have excellent thermal conductivity, and aluminum fins increase the heat dissipation area. The continuous turbulent flow of air between the fins enhances the heat exchange effect, significantly improving heat transfer efficiency.

- High Pressure Resistance: Copper tubes can withstand high pressure, ensuring stable system operation and reducing the risk of leaks or other faults.

- Lightweight and Compact: Aluminum fins are lightweight, and the overall structure is compact, occupying minimal space. This facilitates installation and layout, saving building space.

- Long Service Life: Copper tubes have good corrosion resistance, and aluminum fins are not prone to rust. Under normal operating conditions, copper-tube aluminum-fin coils have a long service life.

- Aesthetic Appearance: After processing, the surface is smooth and neat, matching various architectural decoration styles.

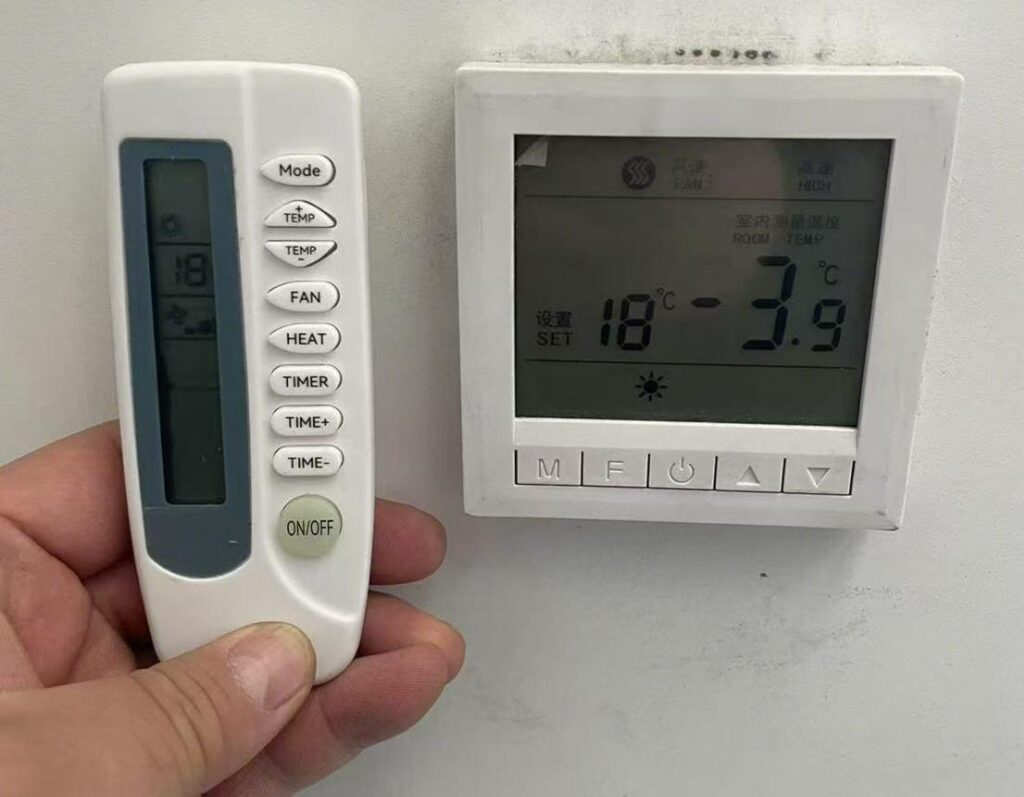

Controller: Room Thermostat

Basic Functions

- Can control the fan to operate at three speeds (high, medium, low) and adjust the wind speed.

- Controls the opening/closing of the electric valve to switch between cooling and heating modes and adjust the temperature.

- Allows setting temperature thresholds (upper and lower limits) to automatically start/stop the equipment.

Operation Methods

Common types include mechanical and electronic thermostats. Mechanical thermostats are operated via knobs or toggle switches, offering simple and direct control. Electronic thermostats typically feature LCD displays to visually show information such as temperature and wind speed, and are operated via buttons or touchscreens for more convenient and intelligent control.

Control Modes

There are two control modes: manual and automatic.

- Inmanual mode, users can adjust wind speed and temperature as needed.

- Inautomatic mode, the controller automatically adjusts the wind speed and electric valve status based on the set temperature and actual indoor temperature.

Communication Functions

Some advanced controllers are equipped with communication interfaces (VÍ DỤ., BACnet, Modbus) that can connect to building automation systems, enabling centralized monitoring, management, remote operation, fault diagnosis, and energy consumption analysis.

Installation and Usage

- Cài đặt: Mounted on the indoor wall for easy operation and observation.

- Usage: First set appropriate parameters such as temperature, wind speed, and mode. During use, adjust settings according to actual needs and environmental changes.

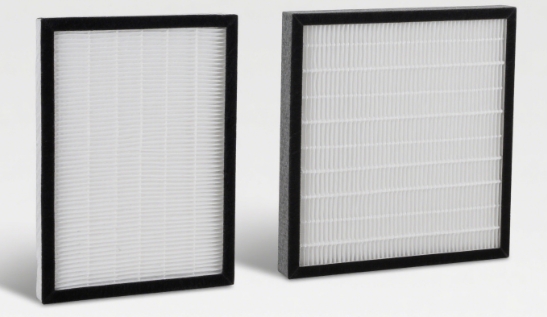

Filter: Primary and intermediate filters(G1-G4 & F5-F9)

Primary Filters

- Filtration Class: Primary filters serve as pre-filtration, capable of removing larger particles such as dust, hair, and fibers. Their filtration efficiency is relatively low, typically achieving 20%–80% efficiency for particles larger than 5μm.

- Materials: Common materials for primary filters include non-woven fabric, nylon mesh, and metal wire mesh, with a simple structure.

- Function: As the first-stage filtration, primary filters remove large particulate contaminants to protect medium-efficiency filters and downstream equipment, extending their service life.

- Replacement Cycle: Due to their role in intercepting large particles first, primary filters have a relatively small dust holding capacity and clog more quickly, requiring a shorter replacement cycle—generally every 1–3 months.

- Application Scenarios: Primary filters are widely used at the front end of general ventilation systems.

Medium-Efficiency Filters

- Filtration Class: Medium-efficiency filters have higher filtration efficiency than primary filters, mainly targeting particles between 1μm and 5μm, with an efficiency of 40%–95% (for particles of the corresponding size).

- Materials: Medium-efficiency filters commonly use materials like glass fiber and synthetic fiber, which have finer fibers and a relatively more complex manufacturing process.

- Function: These filters further remove smaller particles to improve air cleanliness, providing cleaner air for indoor environments while reducing the load on high-efficiency filters (if present).

- Replacement Cycle: The replacement cycle for medium-efficiency filters is relatively longer, about 3–6 months, though it is specifically affected by the usage environment and air quality.

- Application Scenarios: Medium-efficiency filters are typically installed after primary filters and are used in places with higher air quality requirements, such as fan coil systems in hospitals, laboratories, high-end office buildings, vân vân.