Factory Air Curtain for Improved Production Efficiency and Employee Comfort

Normally there are two types of 産業用エアカーテン,one is vertical type air curtain,which is install on the two side of the door, suitable for 4-5m width door

the other is a horizontal type air curtain which can used for max 6-8m height door, with the max air speed can up to 30m/s

工場, being unique environments with high ceilings and large areas, often face challenges related to significant temperature differences between indoor and outdoor spaces and inadequate insulation. これらの問題に対処するには, the use of air curtains in factories can effectively isolate indoor and outdoor air interactions, enhancing the working environment for employees and, simultaneously, improving factory production efficiency.

温度制御

- Effective Temperature Isolation: Factory air curtains effectively isolate indoor and outdoor temperature differences. In summer, the machine prevents hot air from entering, 内部を涼しく保つ. Conversely, in cold winters, the air curtain (heated air curtain) 暖かい空気を生成します, preventing cold air from entering and maintaining a warm indoor environment. This temperature control enhances employee efficiency and ensures stable product quality.

Air Pollution Reduction

- Reducing Indoor and Outdoor Air Pollution: Air curtains can create a barrier against outdoor dust and pollutants, maintaining fresh indoor air. This improves the overall quality of the working environment and ensures the hygiene and safety of products.

Choosing Factory Air Curtains

When selecting air curtains for factories, consider the following aspects:

- サイズと設置位置: Choose an air curtain size that matches the factory entrance width to cover the entrance effectively. Install the machine in a position to maximize its effectiveness.

- 材料と外装デザイン: The air curtain’s material should be durable and corrosion-resistant to withstand the factory’s high-intensity environment. The exterior design should coordinate with the factory’s overall style, enhancing its image.

- パフォーマンスおよび制御システム: エアカーテンは、屋内と屋外の温度を効果的に分離するために、強いエアフローと信頼性の高いパフォーマンスを持つ必要があります. Modern air curtains equipped with intelligent control systems can adjust settings based on actual needs, improving factory operational efficiency.

Maintenance of Factory Air Curtains

To ensure the normal operation of factory air curtains, 定期的な清掃とメンテナンスが必要です. Periodically clean external surfaces, check for loose internal components, inspect electrical connections, and ensure proper fan operation. Timely corrective measures should be taken for common malfunctions.

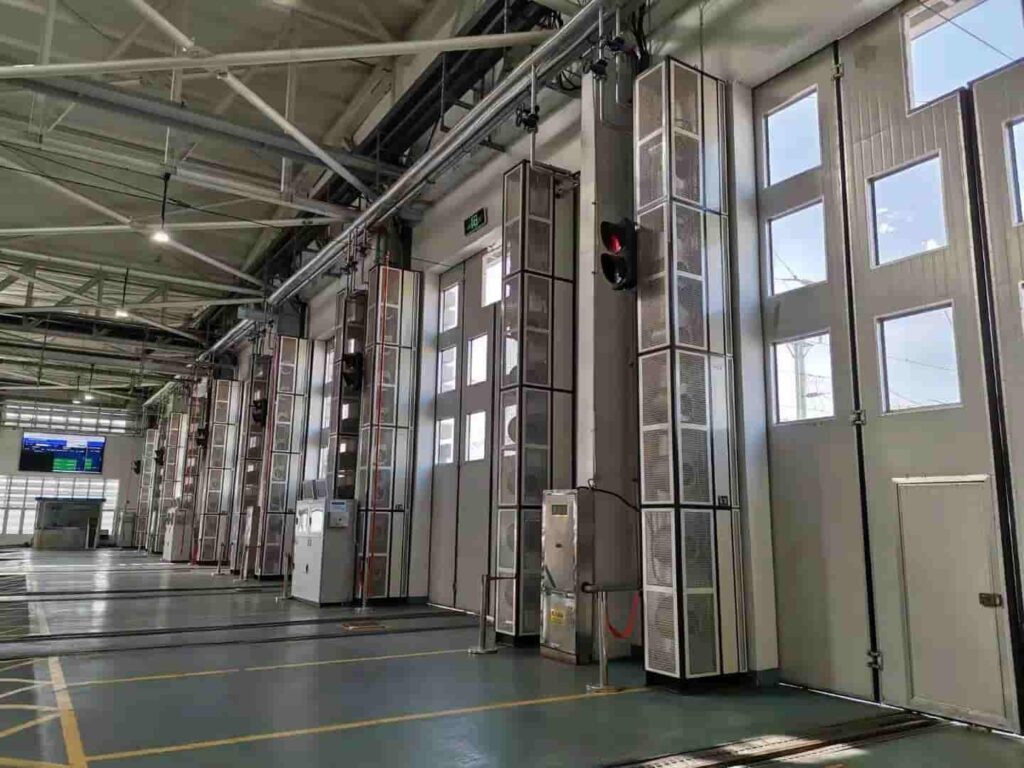

ケーススタディ: Application of Air Curtains in an Automotive Manufacturing Plant

背景

A certain automotive manufacturing plant faced a decline in employee efficiency and instances of heatstroke during the high-temperature summer season. To improve the working environment and enhance production efficiency, they decided to introduce air curtains.

特定のソリューション

Factory Parameters: The plant covers an area of 5000 平方メートル, with six main entrances. ドアサイズはそうです 4000 (length) * 5200 (height) (んん).

エアカーテンパラメーター:

- Model A: Size – 5409005200 (んん) / Motor – 380V8.8KW / Airflow – 40000m3/s

- uantity: 12 ユニット

- Product Specification: Side-blow centrifugal air curtains (installed on both sides of the doors)

- 制御システム: The air curtains are equipped with an intelligent control system, automatically adjusting airflow and operating time based on actual needs.

効果

By installing factory air curtains, the plant’s entrances formed an airflow barrier, effectively preventing outdoor hot air from entering and maintaining a cool and comfortable indoor temperature. さらに, the air curtains reduced outdoor air pollution, improving the overall working environment quality.

結果

After introducing air curtains, employees at the automotive manufacturing plant were no longer affected by high temperatures, resulting in a significant increase in efficiency. Employee comfort and motivation also improved, further enhancing production efficiency. Moreover, the application of air curtains contributed to the growth of the plant’s performance.

結論

The successful application of factory air curtains not only resolves indoor and outdoor temperature interaction issues but also enhances employee working efficiency and comfort, driving overall business development. For other automotive manufacturing plants or production workshops, the use of factory air curtains is a solution worth considering. When selecting and using these machines, consider factors such as size, 材料, パフォーマンス, and control systems, and conduct regular maintenance to ensure optimal performance.