1. Что такое промышленная воздушная завеса?

Пояснение к промышленным воздушным завесам

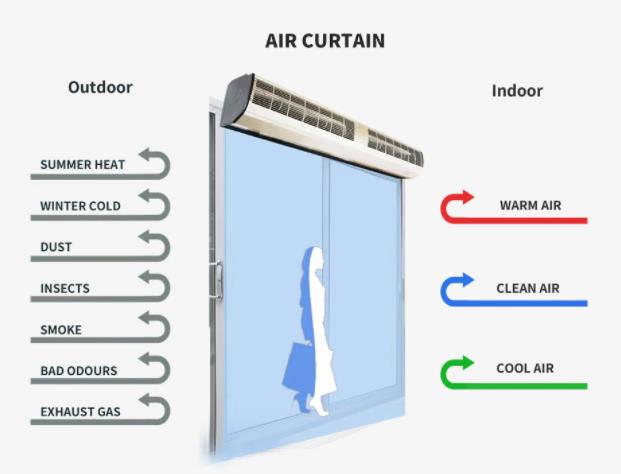

Промышленная воздушная завеса устанавливается над или вдоль входа на промышленные объекты., например, склады, заводы, и холодильные склады. Его основная функция — создание невидимого воздушного барьера, разделяющего различные среды., эффективно предотвращает воздухообмен между внешним и внутренним пространством.

История промышленных воздушных завес

Концепция воздушных завес существует с начала 20 века., значительно развивается на протяжении десятилетий для удовлетворения растущих потребностей различных отраслей промышленности.. история промышленных воздушных завес отражает непрерывный путь инноваций, направленных на повышение эффективности., безопасность, и экологический контроль в промышленных условиях

Функция промышленных воздушных штор

Контроль температуры: Поддержав разделение между внутренними и наружными средами, Промышленные воздушные шторы помогают сохранить желаемую внутреннюю температуру. Это особенно важно для объектов, требующих строгого регулирования температуры, такие как холодные единицы хранения.

Энергоэффективность: Воздушные шторы минимизируют потерю нагреваемого или охлажденного воздуха, таким образом уменьшая энергию, необходимую для контроля климата. Это приводит к значительной экономии энергии и снижению эксплуатационных расходов.

Профилактика загрязняющих веществ: Эти устройства предотвращают пыль, пары, насекомые, и другие загрязняющие вещества от входа в объект, обеспечение более чистой и более безопасной рабочей среды.

Улучшенный комфорт: Сократив проекты и поддержав стабильную внутреннюю температуру, Воздушные шторы улучшают уровень комфорта как для работников, так и для посетителей.

Повышенная безопасность: В промышленных условиях с высоким трафиком, Воздушные шторы могут улучшить видимость, уменьшив необходимость в физических барьерах, таким образом повышая безопасность.

Рабочие принципы

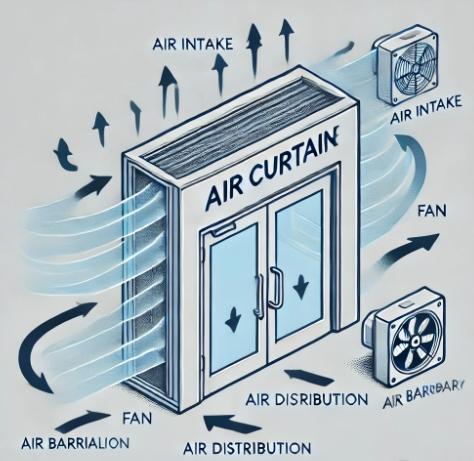

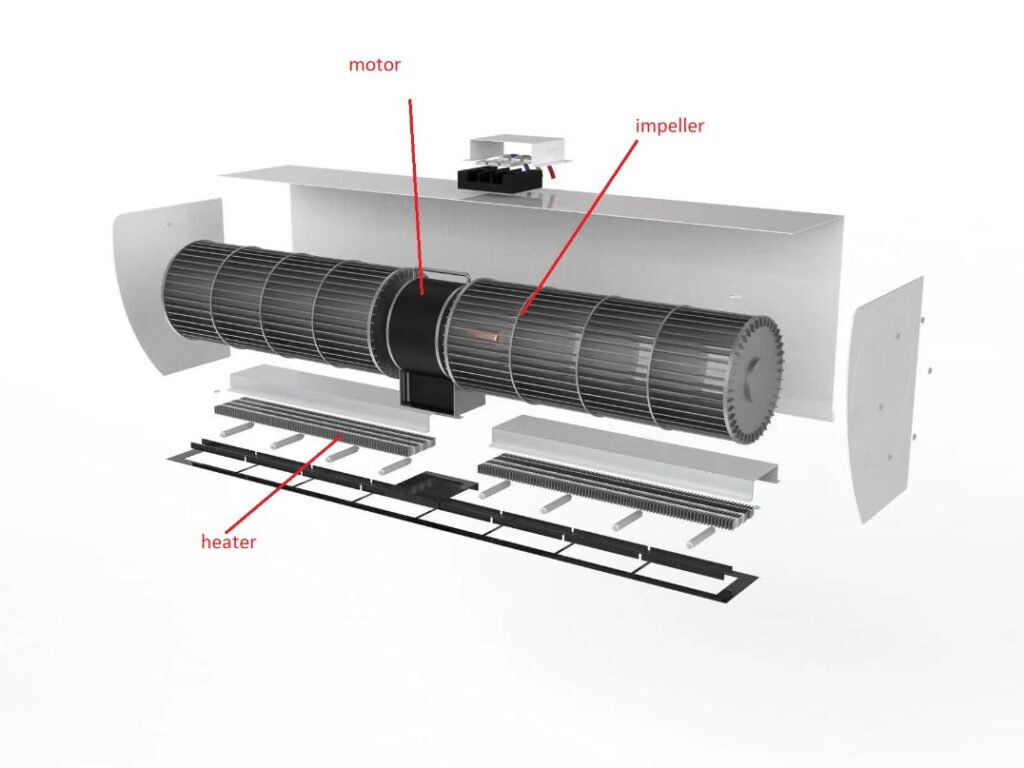

Промышленные воздушные шторы работают на основе принципа создания высокоскоростного воздушного потока, который действует как невидимый барьер между различными средами. Этот воздушный барьер помогает поддерживать желаемые условия внутри промышленного объекта, предотвращая обмен воздухом, загрязняющие вещества, и температура. Вот подробное объяснение принципа работы:

2. применение промышленных воздушных штор

Логистика и склады

Изоляция дверного проема: На больших складах и логистических центрах, Воздушные шторы эффективно предотвращают обмен горячим и холодным воздухом, поддержание стабильных внутренних температур, Особенно в часто открываемых дверях.

Пыль и профилактика насекомых: Воздушные шторы также предотвращают пыль, насекомые, и другие загрязняющие вещества от входа на склад, обеспечение чистоты и безопасности хранимых товаров.

Холодные помещения для хранения и охлаждения

Контроль температуры: Средства для хранения и охлаждения холодного хранения хранят скоропортящиеся продукты и другие чувствительные к температуре предметы. Воздушные шторы помогают поддерживать низкотемпературную среду и снизить потребление энергии.

Снижение мороза: Предотвращая тепло, влажный воздух от входа, Воздушные шторы уменьшают возникновение мороза внутри холодного хранения, тем самым снижая частоту разморожения и затраты.

Производственные заводы

Изоляция мастерской: На производственных заводах, Различные мастерские могут иметь различную температуру, влажность, или требования к чистоте. Воздушные шторы эффективно изолируют эти семинары, поддержание их соответствующих условий окружающей среды.

Контроль загрязнения: Воздушные шторы предотвращают вредные газы, дымка, или другие загрязняющие вещества от распространения в другие районы, Защита здоровья сотрудников и производственную среду.

Пищевые заводы

Гигиенический контроль: На пищевых заводах, Воздушные шторы блокируют насекомых и другие загрязняющие вещества от въезда в зоны обработки, Обеспечение гигиенической и безопасной пищевой среды.

Управление температурой: Они помогают поддерживать стабильные температуры в зонах обработки, Предотвращение внешних колебаний температуры от влияния на качество пищи.

Электроника и точность производства

Чистые комнаты: Электроника и точное производство требуют строгого контроля над пылью и температурой. Воздушные занавески у входов в чистую комнату обеспечивают эффективный воздушный барьер, поддержание чистоты в помещении.

Статическая профилактика: Некоторые воздушные шторы предназначены для уменьшения статического наращивания, Защита деликатных электронных компонентов.

Химическая и фармацевтическая промышленность

Безопасность: В областях, обрабатывающих опасные химические вещества, Воздушные шторы предотвращают распространение вредных газов, Защита других областей и персонала.

Экологическая изоляция: Они изолируют разные области процесса, предотвращение перекрестного загрязнения и улучшения качества производства.

Входы семинара

Вход автомобиля: На входах на семинар, Особенно там, где происходит тяжелое движение транспортных средств, Воздушные шторы предотвращают привлечение внешней пыли и загрязняющих веществ в помещении автомобилями, Сохранение мастерской в чистоте.

3. Тип промышленных воздушных занавесок

По направлению воздушного потока или метода установки

Горизонтальные промышленные воздушные шторы являются наиболее распространенным типом и обычно устанавливаются над дверными проемами или отверстиями. Они создают горизонтальный поток воздуха, который вниз вниз по всему отверстию, формирование невидимого барьера

Вертикальные промышленные воздушные шторы устанавливаются по бокам дверных проемов или отверстий, и они создают вертикальный поток воздуха, который дует горизонтально по всему входу. Они менее распространены, но полезны в определенных приложениях, где горизонтальные воздушные шторы могут быть не практичными

По функции

Стандартные воздушные занавески: предназначены для создания воздушного барьера, который отделяет внутреннюю и наружную среду. Этот тип воздушной занавески без функции отопления,Это не подходит для использования в холодной зоне.

Нагретые воздушные занавески: оснащены отоплением, которые нагревают воздух до того, как он взорван по всему входу. Они особенно полезны в холодном климате или в зимние месяцы, По мере того, как они помогают поддерживать теплую внутреннюю среду, предотвращая попадание холодного воздуха, а также обеспечивает дополнительное отопление.

Охлажденные воздушные занавески: также известный как холодные воздушные занавески, используются в холодных хранилищах, супермаркеты, и другие места, где поддержание низкой температуры имеет решающее значение. Они дуют холодный воздух вниз, чтобы предотвратить въезд теплого воздуха, тем самым сохраняя прохладную среду внутри.

4. Выбор Промышленные воздушные занавески

На основании размера двери

Ширина и высота: Измерьте ширину и высоту дверного проема или отверстия, где будет установлена воздушная занавеска. Воздушная занавеска должна быть достаточно широкой, чтобы покрыть всю ширину и генерировать достаточный воздушный поток, чтобы добраться до полу.

Несколько единиц: Для широких отверстий, Подумайте об использовании нескольких подразделений воздушного занавеса, расположенных рядом.

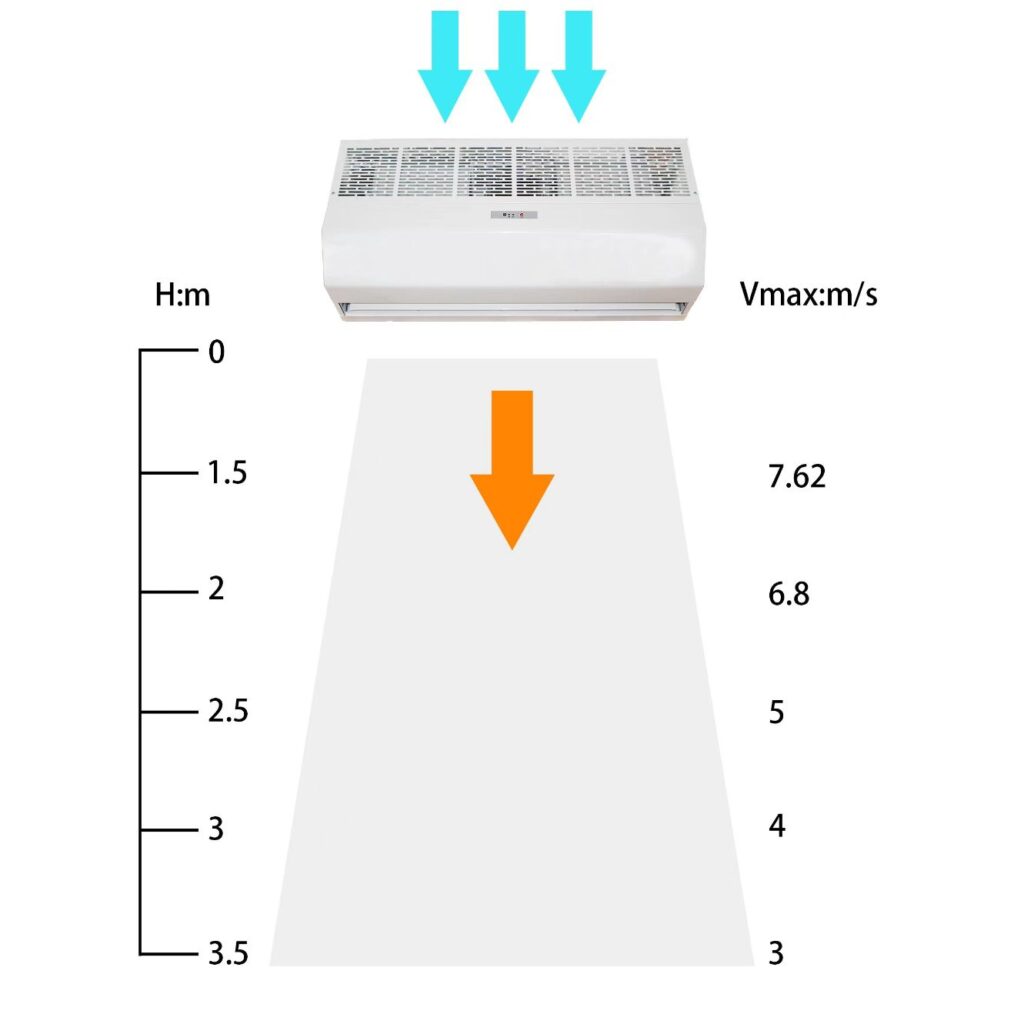

На основании высоты установки

Высота монтажа: Определите высоту, на которой будет установлен воздушный занавес. Воздушные шторы имеют различные возможности производительности, основанные на их высоте монтажа

На основании среды использования

Факторы окружающей среды: Учитывать такие факторы, как влажность, пыль, и химическое воздействие в окружающей среде,Тогда мы можем использовать воздушную занавеску отрасли из нержавеющей стали..

На основе скорости и объема воздушного потока

Скорость воздуха: Выберите воздушную занавеску с достаточной скоростью воздушного потока, чтобы создать сильный барьер. Более высокие скорости необходимы для областей со значительными различиями в давлении или где присутствуют сильные черновики.

Объем воздуха: Убедитесь, что устройство может перемещать достаточный объем воздуха, чтобы эффективно покрыть дверной проем

Контроль температуры:

Стандарт против. Нагретый против. Охлаждены: Выберите между стандартом, нагретый, или охлажденные воздушные шторы на основе потребностей контроля температуры.

На основе энергоэффективности и контроля шума

Эксплуатационные расходы: Рассмотрим энергопотребление воздушного занавеса и его влияние на эксплуатационные расходы. Энергоэффективные модели могут обеспечить долгосрочную экономию. Мы можем выбрать дверной переключатель или датчик двери для воздушной занавески, чтобы сэкономить энергию.

Сравнение бренда и качества

Гарантия и поддержка: Убедитесь, что производитель предлагает хорошую гарантию и надежную поддержку клиентов. Cdairtech предоставляет 2 -летнюю гарантию после установки. И онлайн -поддержка 7*24 часов все время.

5. Установка и обслуживание промышленных воздушных штор

Шаги установки

Прочитайте руководство: Тщательно прочитайте руководство по установке производителя и руководящие принципы.

Проверьте компоненты: Убедитесь, что все компоненты и аксессуары присутствуют и в хорошем состоянии.

Инструменты и оборудование: Соберите все необходимые инструменты и оборудование, такие как тренировки, отвертки, измерительная лента, уровень, и монтажные кронштейны.

Измерьте отверстие: Измерьте ширину и высоту дверного проема или отверстия, чтобы убедиться, что воздушная занавеска - правильный размер.

Определить монтажную позицию: Решите, будет ли воздушная занавеска установлена горизонтально над дверью или по вертикали по бокам, На основании конкретного приложения.

Отметьте монтажные точки: Используйте уровень, чтобы отметить точки монтажа на стене или дверной раме. Убедитесь, что оценки находятся на уровне и равномерно распределены.

Буровые отверстия: Отверстия сверла в отмеченных точках для монтажных кронштейнов. Используйте соответствующие буровые биты на основе материала стены.

Установите кронштейны: Закрепите монтажные кронштейны к стене или раме, используя соответствующие винты и якоря

Поднять воздушную занавеску: С помощью помощника, Поднимите воздушный занавес и выровняйте его с помощью монтажных кронштейнов.

Закрепить устройство: Прикрепите воздушную занавеску к монтажным кронштейнам и закрепите ее, используя болты или винты, как указано производителем.

Проверьте выравнивание: Убедитесь, что воздушная занавеска правильно выровнена и ровно для равномерного распределения воздушного потока.

Источник питания: Убедитесь, что источник питания отключен перед какими -либо электрическими соединениями.

Проводка: Подключите воздушную занавеску к источнику электроэнергии в соответствии с диаграммой проводки производителя. Это может включать подключение проводов к выходу питания или подключение устройства к электрической системе здания.

Соответствие безопасности: Убедитесь, что все электрические соединения соответствуют локальным электрическим кодам и стандартам.

Включите власть: Включите источник питания и протестируйте воздушную занавеску, чтобы убедиться, что он работает правильно.

Регулировка воздушного потока: Отрегулируйте направление воздушного потока и настройки скорости по мере необходимости, чтобы создать эффективный воздушный барьер.

Проверьте операцию: Убедитесь, что воздушная занавеса активирует и деактивирует должным образом, когда дверь открыта и закрыта

Ежедневное обслуживание и уход

Регулярная уборка: Очистить воздушные фильтры, впускные решетки, и периодически разряжать сопла.

Обычные проверки: Провести обычные проверки всех компонентов, включая лезвия вентилятора, мотор, и монтажное оборудование.

Своевременный ремонт: Обратно решить любые выявленные проблемы для предотвращения дальнейшего ущерба.

Профессиональное обслуживание: Расписание профессионального обслуживания в соответствии с рекомендациями производителя для обеспечения оптимальной производительности.

Общие проблемы и устранение неполадок

Недостаточный воздушный поток

Симптомы:

- Слабый воздушный барьер

- Воздух не достигает пола

- Противоречивое воздушное покрытие

Возможные причины и решения:

- Засоренные фильтры или впускные решетки: Проверьте и очистите воздушные фильтры и впускные решетки, чтобы обеспечить правильный воздушный поток.

- Заблокированные форсунки: Проверьте и очистите любые препятствия в сопеле воздушного сброса.

- Настройки скорости вентилятора: Убедитесь, что скорость вентилятора установлена на соответствующий уровень для приложения.

- Изношенные лезвия вентиляторов: Проверьте лопасти вентилятора на наличие износа и замените при необходимости.

Чрезмерный шум

Симптомы:

- Громкая операция

- Необычные вибрации или звуки

Возможные причины и решения:

- Свободное монтажное оборудование: Проверьте и затяните все монтажные болты и винты.

- Изношенные подшипники или моторные проблемы: Проверьте наличие изношенных подшипников или проблем с двигателем и при необходимости замените.

- Несбалансированные фанаты: Осмотрите лопасти вентилятора на наличие баланса и отрегулировать или заменить их по мере необходимости.

- Вибрационная изоляция: Убедитесь, что устройство имеет надлежащую изоляцию вибрации, чтобы уменьшить шум.

Воздушная занавеска не включается

Симптомы:

- Нет власти

- Единица не отвечает на элементы управления

Возможные причины и решения:

- Проблемы с электроснабжением: Проверьте электроснабжение и убедитесь, что устройство правильно подключено и принимает питание.

- Взорвание предохранителя или выключатель с трансляцией: Осмотрите и замените любые взорванные предохранители или сбросите выключатель цепи.

- Неисправный переключатель или панель управления: Проверьте переключатель или панель управления для функциональности и замените при необходимости.

- Проблемы с проводкой: Осмотрите подключения проводки на наличие любых свободных или поврежденных проводов и отремонтировать их.

Снижение эффективности

Симптомы:

- Увеличение потребления энергии

- Снижение производительности

Возможные причины и решения:

- Грязные фильтры или компоненты: Регулярно чистить и поддерживать фильтры и компоненты, чтобы обеспечить эффективную работу.

- Неправильные настройки: Убедитесь, что настройки устройства оптимизированы для конкретного приложения.

- Изношенные или поврежденные детали: Заменить любые изношенные или поврежденные детали для восстановления эффективности.

6. Рыночные промышленные воздушные занавески

Рынок промышленного воздушного занавеса испытывает значительный рост, вызванный растущим акцентом на энергоэффективность, Растущие коммерческие строительные мероприятия, и растущая осведомленность о преимуществах воздушных штор при поддержании климат -контроля в помещении и снижении затрат на энергию.

Размер и рост рынка:

- Глобальный рынок воздушного занавеса был оценен примерно на сумму примерно 1.37 миллиард в 2023 и, по прогнозам, достигнут доллара США 2.46 миллиард за 2029, Растет в CAGR 12.48% от 2024 до 2029 года (Прогноз рыночных данных) (Исследование когнитивного рынка).

- Конкретно, Предполагается, что промышленный сегмент рынка воздушного занавеса станет свидетелем самого быстрого роста в течение этого периода из -за его широкого использования в производственных объектах, склады, и холодильные склады.

Ключевые драйверы:

- Энергоэффективность: Воздушные шторы помогают сократить эксплуатационные расходы, минимизируя потерю энергии из кондиционированных пространств и предотвращение входа внешнего воздуха, приводя к значительной экономии энергии.

- Растущие строительные мероприятия: Увеличение строительства коммерческих зданий, торговые центры, больницы, и производственные мощности, Особенно в развивающихся регионах, таких как Азиатско-Тихоокеанский регион, повышает спрос на воздушные занавески

- Экологический контроль: Воздушные шторы обеспечивают эффективный контроль над температурой, влажность, пыль, и насекомые, что имеет решающее значение в различных промышленных применениях, таких как пищевая переработка, Фармацевтические препараты, и производство электроники.

Региональные идеи:

- Северная Америка: Этот регион доминирует на рынке воздушного занавеса из -за высоких показателей внедрения в коммерческих и промышленных секторах и присутствия крупных игроков рынка.

- Азиатско-Тихоокеанский регион: Ожидается, что будет расти на самом высоком CAGR в течение прогнозируемого периода, обусловлено развитием быстрого развития инфраструктуры и урбанизации в таких странах, как Китай и Индия.

- Европа: Значительная доля рынка из -за строгих правил энергоэффективности и широкого распространения воздушных штор в коммерческих зданиях

Рыночные ограничения:

- Качество установки и дизайна: Плохая практика установки и некачественные конструкции могут препятствовать росту рынка, Поскольку они не могут обеспечить ожидаемую производительность и экономию энергии.

- Стоимость затрат: Первоначальные затраты на установку и необходимость регулярного обслуживания могут стать препятствием для некоторых предприятий, особенно мелкие и средние предприятия